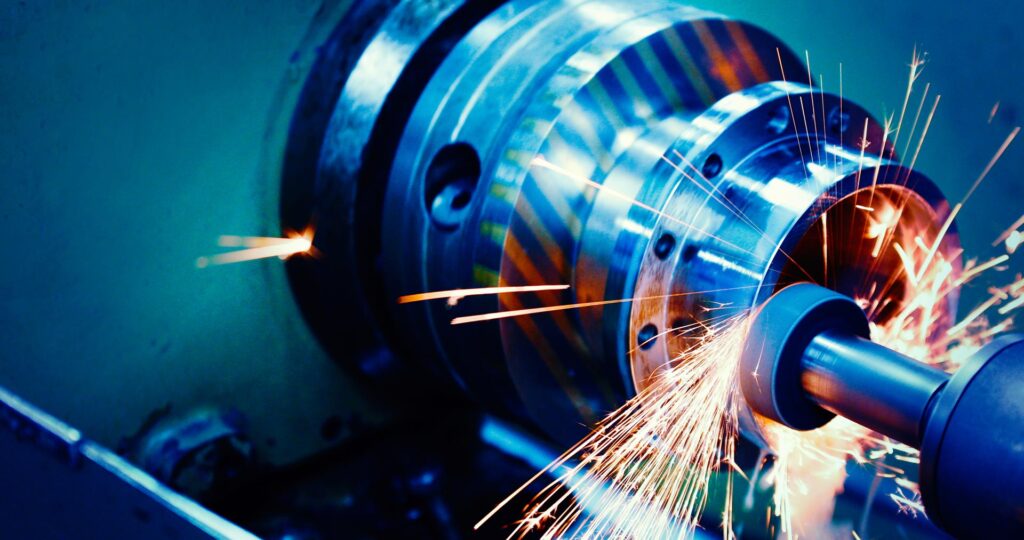

We are your ultimate one stop source in Asia for all your CNC machining needs. From single sample to large production runs, CNC machining offers high accuracy and great flexibility. Utilizing the latest Japanese and German machinery in low labor areas, we deliver high quality products at very competitive pricing.

Supply Concepts specializes in CNC Machining of complex shaped parts, Rapid Sample Development, Fabrication and Assembly of manufactured parts. By combining our in-house expertise with services from suppliers in different fields such as plating, painting or brazing, we are able to provide a complete solution to our customers.

We coordinate capabilities in different fields such as plating, brazing, painting, and powder coating to provide a complete solution to our customers.

More On CNC:

There are number of different parts that can be made using CNC equipment. We can breakdown those in four categories: CNC Turning, CNC Milling, CNC Sheet Metal Stamping, CNC Bending. If you need some guidance to complete the design or make an improvement of your component our experienced staff can help with drawings, reverse engineering, material selection and tooling. We help you choose the top CNC milling Asia can provide with the shortest lead-time and top quality.

Supply Concepts specializes in CNC Machining of complex shaped parts, Rapid Sample Development, Fabrication and Assembly of manufactured parts. By combining our in-house expertise with services from suppliers in different fields such as plating, painting or brazing, we are able to provide a complete solution to our customers.

We coordinate capabilities in different fields such as plating, brazing, painting, and powder coating to provide a complete solution to our customers.

produces parts by “turning” rod material while feeding a cutting tool into the spinning producto. In CNC turning the cutter can be fed into the rotating object at a variety of angles with many tool shapes can being utilized. CNC turning provides an economical way to produce parts that are commonly symmetrical measured from the axis of rotation. Shapes that can be made using CNC turning include a variety of plain, taper, contour, fillet, and radius profiles including threaded surfaces. Although many turned parts use a single axis of rotation, there can be multiple points to allow increased flexibility (e.g. crankshafts). CNC turning can be combined with CNC milling and other processes to make more diverse shapes.

is a cutting process in which material is removed from a block by a rotating tool. In CNC milling the cutting tool is moved in all three dimensions to achieve the desired part. In CNC milling the cutting tool usually rotates about an axis that is perpendicular to the table which holds the material to be cut. A CNC milling machine looks somewhat like a drill press at first glance with a cutting tool protruding down from a rotating spindle. A block of material is placed on a moving table below the cutter. While the cutting tool turns, a computer controls the vertical (Z axis) motion of the cutter and the horizontal (X and Y axis) motion of the block of material. The cutter is guided to move through the material, removing portions to create shapes. Additionally, the material can be turned to various orientations in the middle of the process, while cutting tools of various shapes can be used. Material is usually removed by both the end and the side of the cutting tool.

CNC Milling has several advantages over other manufacturing processes. It is cost effective for short runs. Complex shapes and high dimensional tolerances are possible. Smooth finishes can be achieved. CNC milling can produce almost any 2D or 3D shape provided that the rotating cutting tools can reach the material to be removed. Examples of CNC milled parts include engine components, mould tooling, complex mechanisms, and enclosures.

dies are used to produce high precision metal components which are identical in shape and size. The dimensional accuracy and stability achieved using precision CNC metal stamping is very high and thus, quality made metal stamping dies are critical.

Metal stamping components are utilized everywhere, home electrical switches, computer casings, cars, aircrafts, etc. are just some examples. A highly specialized branch of mechanical engineering, metal stamping technology has grown considerably with the evolution of sophisticated machineries, CAD and CAM.

Sheet metal stamping services: Modular stamping, Progressive die stamping, High-speed stamping, Deep draw stamping, Bore slide stamping, Transfer stamping.

is a process where sheet metal is bent to an angle using, typically a V shaped punch or a die. The sheet is placed between the punch and die which presses down on the sheet. CNC bending provides a low cost method to produce 3D shapes from 2D sheets.

CNC bending is a suitable technique for processing most ductile metals, and primarily for sheet metal designs with one or more bends. Just a few examples of CNC bending applications are brackets, enclosures, cams, chassis, etc. There is generally no special tooling required for CNC bending, with the exception of intricate designs and special bends.

Die casting is a process of casting Aluminium, Zinc and Copper alloy under pressure, which produces precision parts in high volume with low cost. There are two processes of die casting: hot chamber die casting and cold chamber die casting. Die casting machines are typically rated in the amount of pressure they exert on the die. Regardless of their size, the only fundamental difference in die casting machines is the method used to inject molten material into a die. A complete die casting cycle can vary from one second for small components to minutes for casting a large part, making die casting the fastest technique available for producing precise metal parts. Supply Concepts utilizes the fastest methods of production in Asia to produce quality products at significantly lower cost than in other regions.

Die casting is an economical process providing a wider range and shapes of components than any other manufacturing technique.

Die cast parts have a long service life and can be manufactured to complement or enhance the visual appeal of the final product they are used in. Many product designs can be improved or benefit by utilizing die cast parts.

Die casting provides for complex shapes and higher dimensional accuracy/stability than many other mass production processes. Some further machining may be required, depending on the design or application

Die cast parts are stronger than plastic injection moulded products having the same dimensions. Thin wall castings are stronger and lighter than those possible with other casting methods.

Die cast parts can be produced with smooth or textured surfaces and they can be easily finished with a minimum of surface preparation.

Die castings can provide integral fastening elements as part of the design. For many parts, post-machining can be totally eliminated, or, done minimally to bring dimensions to sizes required.

In a cold chamber process, the molten metal is ladled into the cold chamber for each pour. There is less time exposure of the melt to the plunger walls or the plunger. This is particularly useful for metals such as Aluminium and Copper (and its alloys) which alloy easily with Iron at higher temperatures.

In a hot chamber process, the pressure chamber is connected to the die cavity which is immersed permanently in the molten metal. The inlet port of the pressurizing cylinder is uncovered as the plunger moves to the open (un-pressurized) position. This allows a new charge of molten metal to fill the cavity and thus, can fill the cavity faster than the cold chamber process. The hot chamber process is used for metals of a low melting point and high fluidity such as tin, zinc, and lead, that tend not to alloy easily with steel at their melt temperatures.

Extrusion is the process by which long, straight metal parts can be produced. The cross-sections that can be produced vary from solid round, rectangular, L shapes, T shapes, Tubes and, many other different types. Extrusion is done by squeezing metal into a closed cavity through a tool, known as a die, using either a mechanical or hydraulic press.

Extrusion produces compressive and shear forces in the stock. No tensile is produced, which makes high deformation possible, without tearing the metal. The cavity in which the raw material is contained is lined with a wear resistant material. This can withstand the high radial loads that are created when the material is pushed by the die. Extrusions often minimize the need for secondary machining, but, are not of the same dimensional accuracy or surface finish as machined parts.

Cold Extrusion: Cold extrusion is the process done at room temperature or slightly elevated temperatures. This process can be used for most materials,subject to designing robust enough tooling that can withstand the stresses created by extrusion. Examples of the metals that can be extruded are lead, tin, aluminium alloys, copper, titanium, molybdenum, vanadium and steel. Examples of parts that are cold extruded are collapsible tubes, aluminium cans, cylinders and gear blanks. The advantages of cold extrusion are:

– No oxidation takes place.

– Good mechanical properties provided the temperatures created are below the re-crystallization temperature.

– Good surface finish with the use of proper lubricants.

Hot Extrusion: Hot extrusion is done at fairly high temperatures, approximately 50 to 75% of the melting point of the metal. The pressures can range from 35-700 MPA (5076 – 101,525 PSI). Due to the high temperatures/pressures required and their detrimental effect on the die life, as well as other components, good lubrication is necessary. Oil and graphite work at lower temperatures whereas at higher temperatures, glass powder is used.

Typical parts produced by the hot extrusion process are trim parts used in automotive and construction applications, window frame members, railings and aircraft structural parts.

Metal stamping components are utilized everywhere, home electrical switches, computer casings, cars, aircrafts, etc. are just some examples. A highly specialized branch of mechanical engineering, metal stamping technology has grown considerably with the evolution of sophisticated machineries, CAD and CAM.

Sheet metal stamping services: Modular stamping, Progressive die stamping, High-speed stamping, Deep draw stamping, Bore slide stamping, Transfer stamping.

Each of the metal alloys available for die casting offer particular advantages for the completed part:

Zinc – The easiest alloy to cast, it offers high ductility, high impact strength and is easily plated. Zinc is economical for small parts, has a low melting point and promotes long die life.

Aluminium – This alloy is lightweight, while possessing high dimensional stability for complex shapes and thin walls. Aluminium has good corrosion resistance and mechanical properties, high thermal and electrical conductivity, as well as good strength at high temperatures.

Magnesium – The easiest alloy to machine, magnesium has an excellent strength-to-weight ratio and is the lightest alloy commonly die cast.

Copper – This alloy possesses high hardness, high corrosion resistance and the highest mechanical properties of any alloys cast. It offers excellent wear resistance and dimensional stability, with strength approaching that of steel parts.

Lead and Tin – These alloys offer high density and are capable of producing parts with extremely precise dimensions. They are also used for special forms of corrosion resistance.

CNC bending is a suitable technique for processing most ductile metals, and primarily for sheet metal designs with one or more bends. Just a few examples of CNC bending applications are brackets, enclosures, cams, chassis, etc. There is generally no special tooling required for CNC bending, with the exception of intricate designs and special bends.

Die casting is one of the fastest and most cost-effective methods for producing a wide range of components. However, to achieve maximum benefits from this process, it is critical that designers collaborate with the die caster at an early stage of product design and development. Consulting with the die caster during the design phase will help resolve issues affecting tooling and production, while identifying the various trade-offs that could affect overall costs. For example, parts having external undercuts or projections on sidewalls often require dies with slides. Slides increase the cost of the tooling, but may result in reduced metal use, uniform casting wall thickness or, other advantages. These savings may offset the cost of tooling, depending upon the production quantities, providing overall economies realized over the life of the project.

No matter what your metal fabrication needs are, Supply Concepts in Asia can offer the right solution: from single part, or sub-assembly, to turnkey solutions for mechanical and electrical assemblies. We have the technology, equipment, and the experience, to fabricate customized metal products from aluminium, steel, zinc plated steel, stainless steel, brass and copper. Designs that require CNC machining of surfaces or components can be accommodated.

We can supply polished, galvanized, zinc coated, painted, or powder coated finishes. Coupled with our accurate and reliable metal fabricating equipment, we guarantee precision and consistency. You’ll be taking advantage of the best metal fabrication Asia can produce.

We offer:

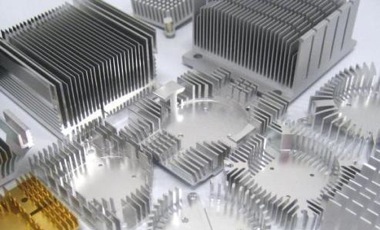

sinks are devices that improve heat dissipation from a hot surface to cooler ambient one. A heat sink does this by increasing the surface area that is in contact with cooling media.

are relatively inexpensive; once a design is made the manufacturing process is highly automated. Aluminium being the most common material used offers and inexpensive thermal conductor material. Extruded heat sinks are used for most general applications. Depending on the design, fin pitch, and base thickness, they can be low to high performers. The basic con is they are limited in their dimensions being that they are based on an aluminium extrusion with a given shape.

are made from a piece of metal being stamped out in a press. A tool is made to the form of the heat sink; the metal is then moved through a stamping which creates the heat sink. This is a highly automated process and once the heat sink design is complete and the prototypes checked, the actual production is a relatively simple. Stamped heat sinks are generally used for low power applications since they are typically low performance option.

are generally designed for large applications that require moderate performance. Bonded fin heat sinks are made by bonding individual fins of metal to a base. The bonding can be done by a thermal epoxy or by brazing. The main advantage to this type of heat sink is it can be used for large applications, such as a DC-DC converter or battery charger. The main drawback is that manufacturing process labor is intense, resulting in a higher cost for the bonded fin assembly.

are best performers if there is ducted air. The flow is directed through a duct directly at the heat sink. Fin pitch can be optimized in the heat sink manufacturing process making it a very high performer. Also, because the heat sink material is folded, there can be an increase in surface area which heat can be dissipated. Fold fin heat sinks have high heat flux density. The drawbacks to this type of heat sink are the cost including manufacturing and ducting necessary in your system. In some cases, plastic can be used to create a folded fin heat sink.

are those that have some kind of forced air mover on them. This might be a fan or blower, most times being attached to the heat sink itself. The air movement provides air flow which helps to cool down a semiconductor hot spot. Though Active Heat Sinks can be very efficient they may not be the best solution long term. Fans are made up of moving parts can break, rendering the heat sink less effective.

are done by compressing a metal, in most case aluminium or copper. Forged heat sinks may be used in a wide variety of applications. They are medium performing heat sinks that are generally inexpensive to make. Their only real limitation being they are somewhat limited in design and air flow management.

are made by a swaging manufacturing process, which is similar to the forging process. The swaging process involves forming the metal to a die. Swaged heat sinks generally are very good performers and ideal for high power applications. Swaged heat sinks tend to be bulky with a limited ability to manage air flow.

are versatile for all applications. Their performance can scale from low to high. Some reasons why thermal engineers use Single Fin are because single fin heat sinks are light weight and feature low profiles which enable them to be deployed in tight spaces

are those that are produced using the skiving process. Fins are made by making very fine cuts from block of metal, usually aluminium or copper. Skived heat sinks can be used in many applications requiring medium to high performance. The skiving process produces heat sinks with very high fin density, creating more surface area for heat dissipation. A drawback is the thick base often seen in skived heat sinks. The Skived heat sink needs to be placed in a forced air flow to be efficient, very much like Active Heat Sinks.

Although heat pipes themselves do not actually dissipate significant amounts of heat, they do effectively transfer heat without a large increase in temperature. This unique transfer capability allows them to transport, or spread heat to a point remote from the heat generator. A variety of basic heat sink technologies benefit from integrating heat pipes which improve conduction paths, reduce overall weight, and raise thermal performance without increasing volume. The availability of a wide range of heat pipes sizes and power handling capabilities make them suitable for the integration in different types of high performance applications. Due to the large variety and diverse nature of customer requirements, most heat sinks using integrated heat pipes are developed specifically for the application. Heat Pipe assemblies have been used to solve thermal problems in motor drives, SMPS, transportation applications, desktop/notebook/computer servers and telecommunication.

With so many complex requirements and heat sink design options, this can be a challenging task. At Supply Concepts thermal engineers understand the factors that impact heat sink specs & design: system airflow, orientation, attachment methods, size, ambient conditions, budget, ect. As designers and manufacturers of hundreds of heat sink solutions, Supply Concepts excels in solving thermal design challenges.

We can deliver a heat sink design, characterize its performance, fabricate, prototypes, and deliver to meet production volumes. Manufacturing a heat sink in Asia is your cost effective alternative.