With years of experience, Supply Concepts can assist you in the design and prototyping stage through to tooling and manufacturing of plastic injection moulding parts in Asia. Our team will ensure you receive all the information needed to make the right decisions about your injection moulding requirements: material selection, colors, packaging and any other aspects.

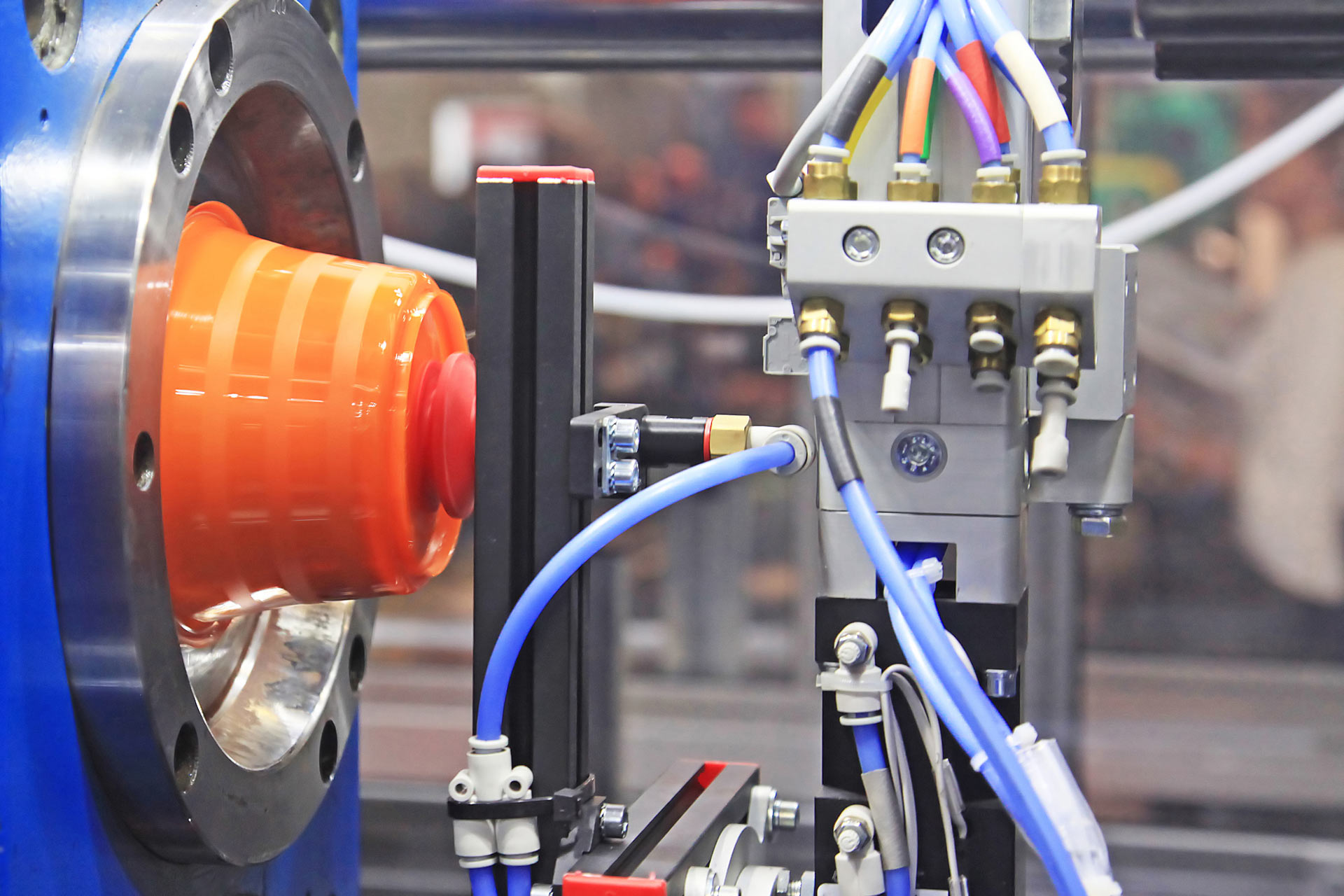

Choosing the right type of plastic for the job is often critical. Supply Concepts can assist you based on the knowledge and track record we have compiled through many years in the injection moulding industry and in plastic part manufacturing. We process a wide selection of thermoplastic materials including PVC, Nylon, Polycarbonate, Noryl, Styrene, Polystyrene, Polypropylene & Acrylic. Injection moulding parts can range from 3 grams to 10,000 grams. Plants incorporate use of robotic assisted part picking, drying and packing to minimize overhead and deliver the lowest possible part cost. When choosing injection moulding suppliers, you can be confident that Supply Concepts will provide the best ratio of cost and quality with our Asia manufacturing operations.

Equipped with the latest CAD software, our injection moulding design team will work from your drawing and design the mould to produce the product exactly as you have specified. By having in house mould designers, toolmakers and mould shop, we have a closed loop evaluation process that enables us to deliver results quickly, accurately and competitively.

We assist with material selection and component design to optimise manufacturing. Supply Concepts will work closely with your project manager as part of your design team and as a strategic sourcing partner. We perform flow process simulation to optimise part concept and tooling design. Gate design analysis, filling, packing, runner balancing and cooling are all optimised. Prototypes are made to validate designs and sample production runs are performed as part of the testing stage to evaluate the final tooling and part designs.

This process utilizes high pressure nitrogen gas to produce hollow injection moulded components resulting in lower weight, shorter cycles and reduced visual sinking. Variants of this process include “external gas moulding” and “internal gas moulding”. These processes allow more design freedom and flexibility. It also allows discreet coring out of a thick product, thicker ribbing and can also eliminate sink marks.

This process is used in the manufacture of complex hollow items leaving a relatively uniform wall section. Water is used to displace polymer melt and provide the packing pressure during the cooling phase of the cycle. Typical examples; manifolds, elbows and water pipes.The suggested advantages of WAIM over GAIM are:

-Thinner residual wall thickness (RWT) – lower material usage.

-Higher cooling rate – particularly where water is circulated.

-Improved internal surface finish.

This process has been most popular in automotive components that are typically thick sectioned. For example: conduits that convey fluids around an engine and car door handles would utilize this process.

MIM is an advanced manufacturing process for forming small, complex, high-precision and high performance metal parts. It is a development of the traditional powder metallurgy (PM) process and has several key advantages. In the PM process, parts with undercuts or projections at right angles to the pressing direction cannot normally be directly made. The MIM process substantially removes this limitation.

Similar to injection moulding but with multiple extruders to produce a single component from two 2 or more different parent materials or colors. Typical applications are soft over-moulding to produce seals or ergonomic soft-touch handles. Examples are : screwdrivers, soft-grip handles, cup-holders and toothbrushes.

Thin wall moulding is defined as a wall thickness of less than 0.025 in (0.62 mm) or a flow length to wall thickness ratio of greater than 200. When compared to standard injection moulding, high melt flow materials are used (30-60 MFI) along with accumulator assist injection and higher injection speeds/pressures. Stack moulds are common.

Recent advances in miniature moulding technology has seen major growth in the area of micro moulding for electronics and medical applications.

Thermoplastic Injection moulding is the most widely used of all plastic processing methods. Injection moulding offers the lowest piece prices available, but tooling prices are generally the highest. The injection moulding machine reduces pelletized raw material into a hot liquid. This “melt” is forced into a cooled mould under tremendous pressure. After the material solidifies, the mould is opened and a finished part is ejected.

Thermoset injection moulding is similar to thermo-plastic injection moulding except that uncured thermoset resins are mixed, injected, and held in a heated mould until cured. As with thermoplastic moulding, the price per piece can be low, but the tooling prices are generally higher.

This method is typically used to create hollow parts; jars, bottles, containers, etc. Part prices for this style of plastic and rubber services are generally higher than injection moulded parts, but, lower than rotationally moulded parts. Tooling costs are moderate.

Rotational moulding uses hollow moulds filled with powdered resin. Low tooling costs and higher piece prices are typical of this process.

Compression moulding services use a slug of hard media pressed between the two halves of a heated mould. After being formed, the part is air-cooled. Both tooling and piece part prices are moderate.

Thermoforming plastic moulding uses sheets of pre-extruded rigid plastic as the feed material. These are heated horizontally and sucked down into hollow one-piece tools.

(Also referred to as In-mould decorating) Mainly used in injection moulding. Robotically placed individual pre-printed decorative labels are loaded during each machine cycle into the mould tool. To assist adhesion during the closing and material flow stages, the label and tool is electrostatic charged.

Plastic welding – various plastic welding processes are employed depending upon part geometry, size and polymer used. Ultrasonic welding, hot-plate welding, vibration welding, laser welding and spin welding can all be used.

Structural foam moulding is a term commonly used to describe components made by the injection moulding process that have a cellular core in which the outer surface is denser than the inner layers. The core of the moulding is of a honeycomb nature and less dense than the outer surface. Can also be referred to as microcellular injection moulding (MuCell). Applications include – Wine corks, Energy absorbing foam, low weight products, impact absorbing pads.

Some plastics, including nylons, will absorb moisture from the atmosphere, which alters their physical properties. Properties affected include brittleness and dimensional stability. Moisture absorption can be as high as 2% of a products weight. A pigment is often applied during the moisture conditioning process to identify treated parts.

All of our facilities are ISO certified. We manufacture products that comply with, or exceed, the specifications supplied by our customers. Supply Concepts perpetually reviews manufacturing processes/procedures and provides ongoing team training to ensure we meet our quality objectives and maximize customer satisfaction.